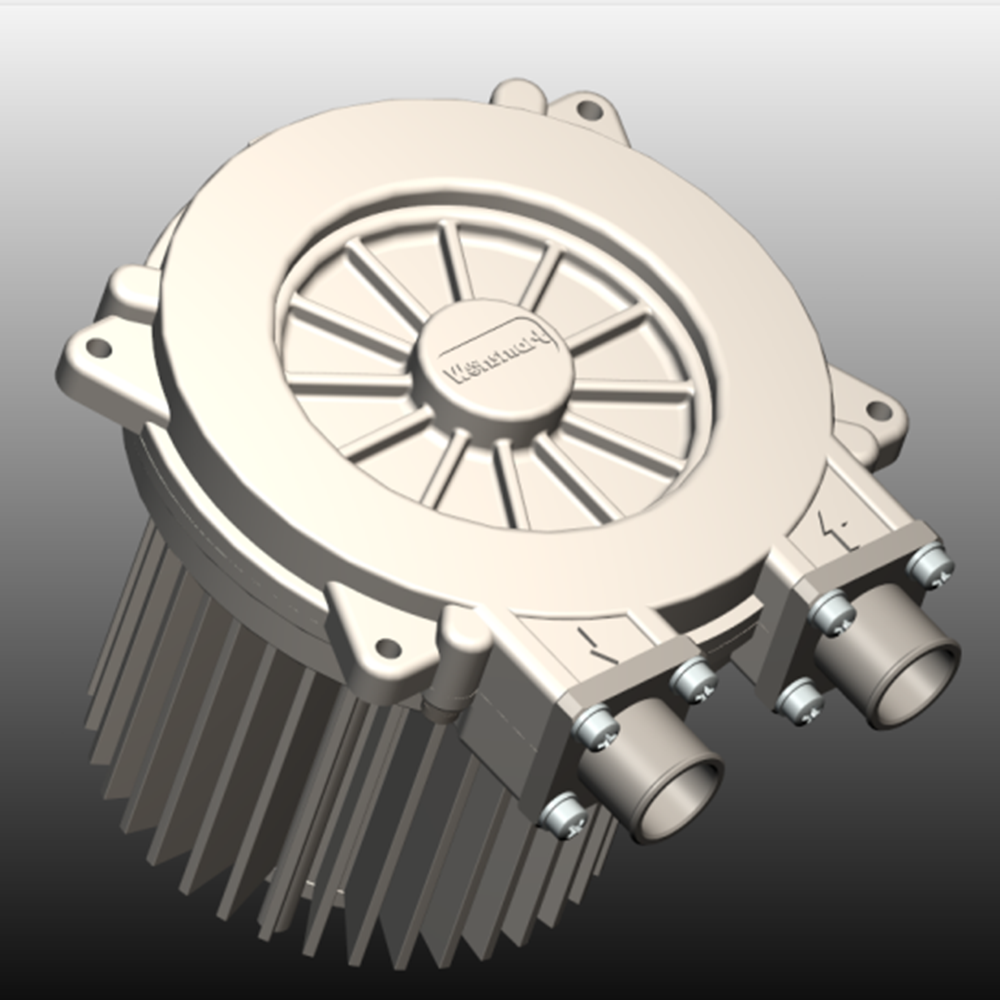

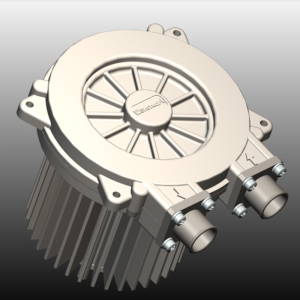

48V high pressure brushless Fuel Cell Electric Ring Blower

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 48vdc

Bearing: NMB ball bearing

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: Plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: CE, RoHS,Reach,ISO9001

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 1.5 Kgs

Housing material:PC

Unit size: D110*H107mm

Motor type:Three Phase DC Brushless Motor

Controller: External

Static pressure: 32kPa

Drawing

Blower Performance

WS145110-48-150-X300 blower can reach maximum 33m³/h airflow at 0 kpa pressure and maximum 32kpa static pressure.It has maximum output air power when this blower run at 18kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 16kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1)WS145110-48-150-x300 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 30,000hours at 20degree C environmental temperature.

(2)This blower needs no maintence;

(3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4)Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Related Product

|

|

|

|

| Part no | WS9070-24-S200 | WS145120-48-170-S200 | WS9290-24-220-X200 |

| Voltage | 24VDC | 48VDC | 24VDC |

| Air pressure | 13.5KPA | 40KPA | 12.5KPA |

| Air flow | 6.9m3/h | 92m3/h | 47m3/h |

| Application | Fuel cell machine | Fuel cell machine | Fuel cell machine;Particulate sampler machine |

FAQ

Q: Can we connect this centrifugal air blower directly onto power source?

A: This blower fan is with BLDC motor inside and it needs a controller board to run.

Q: What kind of power source shall we use to drive this blower fan?

A: Generally, our customers use 48vdc switching power supply or Li-on battery.

Q: Do you also sell controller board for this blower fan?

A: Yes, we can supply adapted controller board for this blower fan.

Ring channel blower

A ring channel blower is used when the pressure or the vacuum is too high for centrifugal ventilators or when a compact construction type is required. Ring channel blowers will also produce less noise than centrifugal or radial ventilators with equal pressure, once the right measures are taken.The broad working area of ring channel blowers is interesting for many applications. This working area closes the gap between high/middle vacuum pumps, high pressure compressors and centrifugal ventilators. It is interesting for various applications because of the installed power, compact construction type, vibration-free functionality and low sound pressure. Based on several applications, the considerations for dimensioning the ring channel blowers will be discussed.

Besides motor protection, several other accessories to ring channel blowers ensure a normal and sustainable working, but influence the output and the pressure in practice as well. Inlet and discharge silencers for pipework, filters and return valves contribute to pressure losses in the system. Filters in particular, especially when polluted, cause pressure losses because of the high speed in the pipework of ring channel blowers. The high speed of the medium(air) also causes pressure losses in pipework and tubes. A fitting reserve in pressure and a sufficient extensive dimensioning of pipework and other system components form an efficient and solid solution. Our sales team can assist you with dimensioning the accessories of ring channel blowers.

Ring channel blowers are applied for aeration of baths. Examples are recreational use, mechanical applications, chemical or biological processes. The needed output or volume results from the calculations of the user, but mostly results from experience. The required pressure can be calculated in the design phase using: the height of the fluid, potential over- or under pressure in the liquid container, specific mass of fluid, pressure loss discharge nozzle or air stones, pressure losses in the pipe work, pressure loss in a filter in a polluted state and the pressure loss in other system components.

Point extraction requires a relatively small diameter of the pipework at the point of extraction, making ring channel blowers with a high vacuum perfect. This way, smoke gasses, sawdust, chips, damps and dust will be suctioned. The needed output is usually known from comparable applications or is experimentally determined. An efficiently designed system minimalizes the pressure losses in transport pipes. This way the pressure loss is mainly determined by the inlet nozzle with a tube or duct and the filter.

Dry blowing is an application where air knives function effectively when they are powered with air pressure of ring channel blowers. The air knife with an air gap of 1,0 mm and an ideal blow mold will pull most ambient air that achieves the best dry scraping effect on the product. TA correct construction of the supply lines will contribute to the preservation of the capacity of the ring channel blower. Flexible tubes in these cases usually have bigger losses than pipework with wide curves. Besides this, you should also take the pressure loss in the inlet filter into consideration. Our sales team can advise you about the required capacity for the air knife and offer the corresponding air knives. The result of the drying is such process and product dependent that this is always determined in practical tests.

Ring channel blowers have a broad range of applications. We attach great value to offer our customers service to full satisfaction. We would like to hear from you how we can realize this.