Cheap price Blower Fan Motor - WS7050-24-V200 – Wonsmart

Cheap price Blower Fan Motor - WS7050-24-V200 – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Voltage:24VDC

Certification: CE, RoHS, ETL, ISO 9001, ISO13485

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 220 grams

Housing material:PC

Unit size: D70mm *H37mm

Motor type:Three Phase DC Brushless Motor

Outlet diameter: OD17mm ID12mm

Controller: external

Static pressure: 6.7kPa

Drawing

Blower Performance

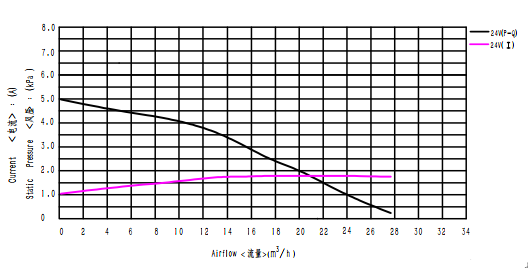

WS7050-24-V200 blower can reach maximum 26m3/h airflow at 0 kpa pressure and maximum 6.7kpa static pressure. It has maximum output air power when this blower run at 3kPa resistance if we set 100% PWM. Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

DC brushless blower advantage:

(1)WS7050-24-V200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000 hours under 20 degree C environmental temperature.

(2)This blower needs no maintence

(3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto CPAP/Bipap/Ventilator machine, and other medical devices.

How to Use the Blower Correctly

This blower can run at CCW direction only.Reverse the impeller running direction can not change the air direction.

Filter onto the inlet to protect the blower from dust and water.

Keep the environmental temperature as low as possible (-20 deg.C~+60 deg.C)to make the blower lifetime longer.

What is centrifugal fan?

A centrifugal fan is a mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. Centrifugal fans often contain a ducted housing to direct outgoing air in a specific direction or across a heat sink; such a fan is also called a blower, blower fan, biscuit blower, or squirrel-cage fan (because it looks like a hamster wheel). These fans increase the speed and volume of an air stream with the rotating impellers.

FAQ

Q: Do you also sell controller board for this blower fan?

A: Yes, we can supply adapted controller board for this blower fan.

Q: How to change impeller speed if we use your controller board?

A: You can use 0~5v or PWM to change speed. Our standard controller board is also with a

potentiometer to change speed conveniently.

Q: What is the MTTF of this centrifugal air blower?

A: MTTF of this centrifugal air blower is 20,000+ hours under 25 C degree.

Q: Can we use this centrifugal air blower to suct water?

A: This blower fan can not be used to suck water. If you need to suck water, you can ask us to choose proper item for this special working condition.

Can we use this centrifugal air blower to suck dust directly?

This blower fan can not be used to suck dust directly.If you need to suck dust, you can ask us to choose proper item for this special working condition.

What can do if the working condition is dirty?

A filter is strongly recommended to assemble onto the the inlet of the blower fan

How to decrease the noise of the blower?

Many of our customers use foam, silicone to fill between blower fan and machine to insulate the blower noise.

Compared with AC induction motor, brushless DC motor has the following advantages:

1. rotor adopts magnets without exciting current. The same electrical power can achieve greater mechanical power.

2. the rotor has no copper loss and iron loss, and the temperature rise is even smaller.

3. the starting and blocking moment is large, which is beneficial to the instantaneous torque required for valve opening and closing.

4. the output torque of the motor is directly proportional to the working voltage and current. The torque detection circuit is simple and reliable.

5. by adjusting the average value of the supply voltage through PWM, the motor can be adjusted smoothly. The speed regulating and driving power circuit is simple and reliable, and the cost is low.

6. by lowering the supply voltage and starting the motor by PWM, the starting current can be reduced effectively.

7. motor power supply is PWM modulated DC voltage. Compared with the sine wave AC power supply of AC variable frequency motor, its speed regulation and drive circuit produce less electromagnetic radiation and less harmonic pollution to the grid.

8. using closed loop speed control circuit, the motor speed can be changed when load torque changes.

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Cheap price Blower Fan Motor - WS7050-24-V200 – Wonsmart , The product will supply to all over the world, such as: Bangladesh, Barbados, Plymouth, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!