Factory Cheap Hot 24v Brushless Blower - 24vdc brushless electric mini centrifugal air blower fan – Wonsmart

Factory Cheap Hot 24v Brushless Blower - 24vdc brushless electric mini centrifugal air blower fan – Wonsmart Detail:

Blower Features

Type: Centrifugal Fan

Applicable Industries:Manufacturing Plant, medical equipment

Electric Current Type:DC

Blade Material:Aluminum

Mounting:industrial assembly

Place of Origin:Zhejiang, China

Brand Name:WONSMART

Model Number:WS7040AL-24-V200

Voltage:24vdc

Certification:ce, RoHS

Warranty:1 Year

After-sales Service Provided: Online support

Product name: 24vdc brushless electric mini centrifugal air blower fan

size: D60*H40mm

Weight: 134g

Bearing: NMB ball bearing

driver board:External

Life time(MTTF): >10,000 hours

Noise:62dB

Motor type:Three Phase DC Brushless Motor

Static pressure:7.6kPa

Drawing

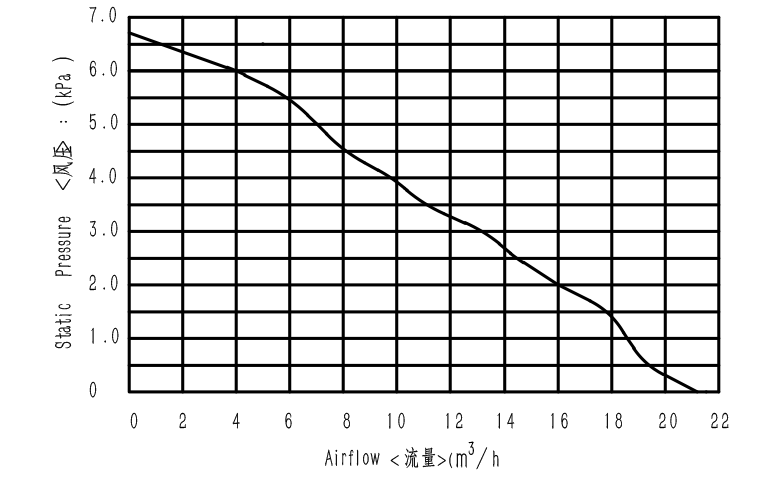

Blower Performance

WS7040AL-24-V200 blower can reach maximum 16m3/h airflow at 0 kpa pressure and maximum 6.5kpa static pressure.When this blower run at 4.5kPa resistance if we set 100% PWM,it has maximum output air power when this blower run at 4.5kPa resistance if we set 100% PWM,it has maximum efficiency.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1)WS7040AL-24-V200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000hours at 20degree C environmental temperature.

(2)This blower needs no maintence;

(3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air cushion machine, CPAP machine,ventilators.

How to Use the Blower Correctly

FAQ

Q: Are you trading company or manufacturer?

A: We are professional manufacturer specialized in Brushlees DC blower more than 10 years, and we export our production to customers directly.

Q: When can I get the price?

A:Usually we will send quotation to customer within 8 hours after we get inquiry from you.

Different number of stator and armature fields as well as how they are connected provide different inherent speed and torque regulation characteristics. The speed of a DC motor can be controlled by changing the voltage applied to the armature. Variable resistance in the armature circuit or field circuit allows speed control. Modern DC motors are often controlled by power electronics systems which adjust the voltage by “chopping” the DC current into on and off cycles which have an effective lower voltage.

Since the series-wound DC motor develops its highest torque at low speed, it is often used in traction applications such as electric locomotives, and trams. The DC motor was the mainstay of electric traction drives on both electric and diesel-electric locomotives, street-cars/trams and diesel electric drilling rigs for many years. The introduction of DC motors and an electrical grid system to run machinery starting in the 1870s started a new second Industrial Revolution. DC motors can operate directly from rechargeable batteries, providing the motive power for the first electric vehicles and today’s hybrid cars and electric cars as well as driving a host of cordless tools. Today DC motors are still found in applications as small as toys and disk drives, or in large sizes to operate steel rolling mills and paper machines. Large DC motors with separately excited fields were generally used with winder drives for mine hoists, for high torque as well as smooth speed control using thyristor drives. These are now replaced with large AC motors with variable frequency drives.

Product detail pictures:

Related Product Guide:

Our mission will be to grow to be an innovative supplier of high-tech digital and communication devices by giving worth added design and style, world-class production, and service capabilities for Factory Cheap Hot 24v Brushless Blower - 24vdc brushless electric mini centrifugal air blower fan – Wonsmart , The product will supply to all over the world, such as: Portugal, Kuwait, New Orleans, We've been proud to supply our products and solutions to every auto fan all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!