High Performance 24v Mini Centrifugal Turbo Fan - 24v dc high pressure air centrifugal blower – Wonsmart

High Performance 24v Mini Centrifugal Turbo Fan - 24v dc high pressure air centrifugal blower – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage:24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries:Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS, ETL

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 490 grams

Housing material:PC

Unit size: D90*L114

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 13 kPa

Drawing

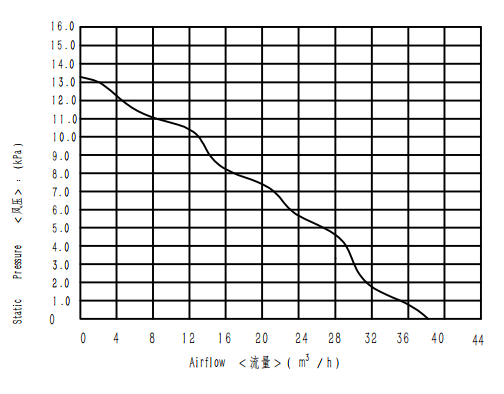

Blower Performance

WS9290B-24-220-X300 blower can reach maximum 38m3/h airflow at 0 kpa pressure and maximum 13kpa static pressure.It has maximum output air power when this blower run at 7kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 7kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS9290B-24-220-X300blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000hours at 20degree C environmental temperature

(2) This blower needs no maintence

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air pollution detector,air bed,air cushion machine and ventilators.

How to Use the Blower Correctly

FAQ

Q: What is the MTTF of this centrifugal air blower?

A: MTTF of this centrifugal air blower is 10,000+ hours under 25 C degree.

Q: Can we use our own logo?

A: Yes, we can print your private logo according to your request.

Q: Can you do our own packaging?

A: Yes, you just provide the package design and we will produce what you want. We also have the professional designer can help you do the packaging design.

What is centrifugal fan?

A centrifugal fan is a mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. Centrifugal fans often contain a ducted housing to direct outgoing air in a specific direction or across a heat sink; such a fan is also called a blower, blower fan, biscuit blower, or squirrel-cage fan (because it looks like a hamster wheel). These fans increase the speed and volume of an air stream with the rotating impellers.

Centrifugal fans use the kinetic energy of the impellers to increase the volume of the air stream, which in turn moves against the resistance caused by ducts, dampers and other components. Centrifugal fans displace air radially, changing the direction (typically by 90°) of the airflow. They are sturdy, quiet, reliable, and capable of operating over a wide range of conditions.

Centrifugal fans are constant-displacement or constant-volume devices, meaning that, at a constant fan speed, a centrifugal fan moves a relatively constant volume of air rather than a constant mass. This means that the air velocity in a system is fixed even though the mass flow rate through the fan is not.

Centrifugal fans are not positive-displacement devices and centrifugal fans have certain advantages and disadvantages when contrasted with positive-displacement blowers: centrifugal fans are more efficient, whereas positive-displacement blowers may have a lower capital cost.

The centrifugal fan has a drum shape composed of a number of fan blades mounted around a hub. As shown in the animated figure, the hub turns on a driveshaft mounted in bearings in the fan housing. The gas enters from the side of the fan wheel, turns 90 degrees and accelerates due to centrifugal force as it flows over the fan blades and exits the fan housing.

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for High Performance 24v Mini Centrifugal Turbo Fan - 24v dc high pressure air centrifugal blower – Wonsmart , The product will supply to all over the world, such as: Qatar, Portland, Estonia, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we have been looking forward to building up a great business relationship with you.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!