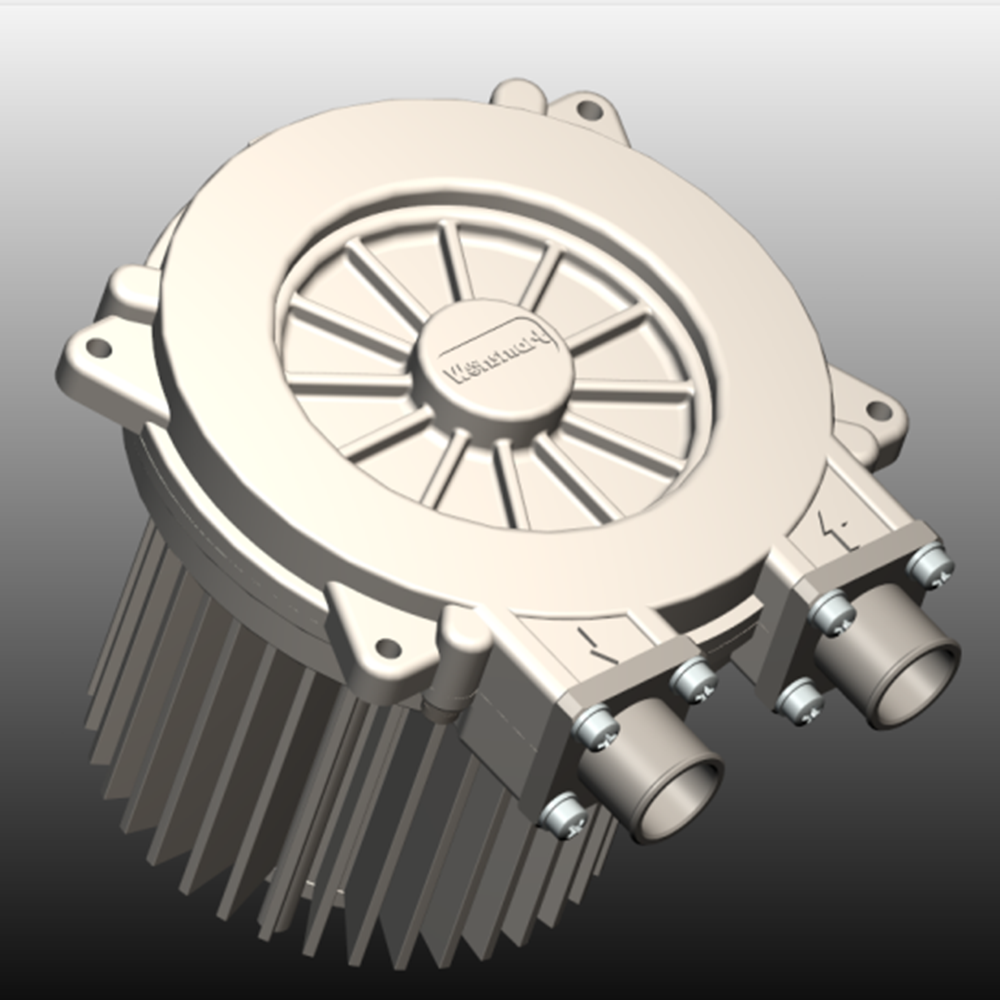

High Quality Air Suction Blower - centrifugal blower for breathing machine ICU ventilator – Wonsmart

High Quality Air Suction Blower - centrifugal blower for breathing machine ICU ventilator – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage:24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries:Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Voltage:24VDC

Certification: ce, RoHS, ETL

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 400 grams

Housing material:PC

Unit size: 90*90*50mm

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 8kPa

Drawing

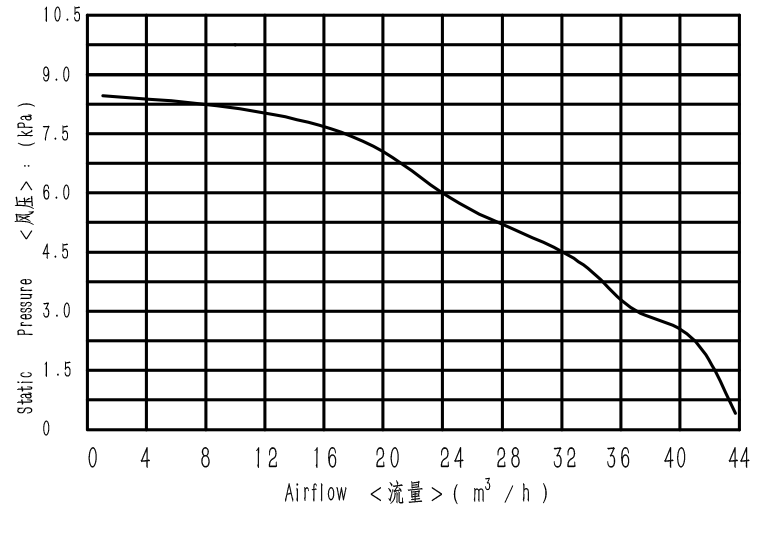

Blower Performance

WS9250-24-240-X200 blower can reach maximum 44m3/h airflow at 0 kpa pressure and maximum 8kpa static pressure.It has maximum output air power when this blower run at 4.5kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 5.5kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1)WS9250-24-240-X200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20 degree C environmental temperature

(2)This blower needs no maintence

(3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air pollution detector,air bed,air cushion machine and ventilators.

How to Use the Blower Correctly

FAQ

Q: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q: What’s your MOQ?

A: It will be no MOQ, If we have the products in stock. We will discuss the MOQ according to customer’s exact situation.

Q: How long is your delivery time?A: The general delivery time is 15-20 days after receiving your order confirmation. Anther, It will only take 1-2 days if we have stock.

A simple DC motor has a stationary set of magnets in the stator and an armature with one or more windings of insulated wire wrapped around a soft iron core that concentrates the magnetic field. The windings usually have multiple turns around the core, and in large motors there can be several parallel current paths. The ends of the wire winding are connected to a commutator. The commutator allows each armature coil to be energized in turn and connects the rotating coils with the external power supply through brushes. (Brushless DC motors have electronics that switch the DC current to each coil on and off and have no brushes.)

The total amount of current sent to the coil, the coil’s size, and what it is wrapped around dictate the strength of the electromagnetic field created.

The sequence of turning a particular coil on or off dictates what direction the effective electromagnetic fields are pointed. By turning on and off coils in sequence, a rotating magnetic field can be created. These rotating magnetic fields interact with the magnetic fields of the magnets (permanent or electromagnets) in the stationary part of the motor (stator) to create a torque on the armature which causes it to rotate. In some DC motor designs, the stator fields use electromagnets to create their magnetic fields which allows greater control over the motor.

At high power levels, DC motors are almost always cooled using forced air.

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for High Quality Air Suction Blower - centrifugal blower for breathing machine ICU ventilator – Wonsmart , The product will supply to all over the world, such as: Belgium, Marseille, Mecca, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.