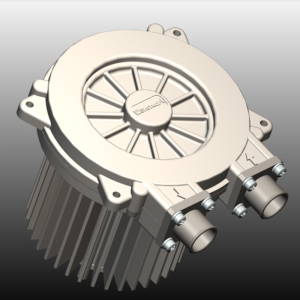

48vdc Li-ion battery powered vacuum cleaner blower

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 48vdc

Bearing: NMB ball bearing

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: aluminium

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 886 grams

Housing material:PC

Size: 130mm*120mm

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 14kPa

Drawing

Blower Performance

WS130120S2-48-220-X300 blower can reach maximum 120m3/h airflow at 0 Kpa pressure and maximum 14kpa static pressure.It has maximum output air power when this blower run at 8.5kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 8.5kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS130120S2-48-220-X300 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20degree C environmental temperature.

(2) This blower needs no maintence

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto vacuum machine,dust collector,floor treatment machine.

How to Use the Blower Correctly

FAQ

Q: Can we connect this centrifugal air blower directly onto power source?

A: This blower fan is with BLDC motor inside and it needs a controller board to run.

Q: Do you also sell controller board for this blower fan?

A: Yes, we can supply adapted controller board for this blower fan.

Q: How to change impeller speed if we use your controller board?

A: You can use 0~5v or PWM to change speed. Our standard controller board is also with a potentiometer to change speed conveniently.

Brushless motors can be constructed in several different physical configurations: In the 'conventional' (also known as inrunner) configuration, the permanent magnets are part of the rotor. Three stator windings surround the rotor. In the outrunner (or external-rotor) configuration, the radial-relationship between the coils and magnets is reversed; the stator coils form the center (core) of the motor, while the permanent magnets spin within an overhanging rotor which surrounds the core. The flat or axial flux type, used where there are space or shape limitations, uses stator and rotor plates, mounted face to face. Outrunners typically have more poles, set up in triplets to maintain the three groups of windings, and have a higher torque at low RPMs. In all brushless motors, the coils are stationary.

There are two common electrical winding configurations; the delta configuration connects three windings to each other in a triangle-like circuit, and power is applied at each of the connections. The Wye (Y-shaped) configuration, sometimes called a star winding, connects all of the windings to a central point, and power is applied to the remaining end of each winding.

A motor with windings in delta configuration gives low torque at low speed but can give higher top speed. Wye configuration gives high torque at low speed, but not as high top speed.

Although efficiency is greatly affected by the motor's construction, the Wye winding is normally more efficient. In delta-connected windings, half voltage is applied across the windings adjacent to the driven lead (compared to the winding directly between the driven leads), increasing resistive losses. In addition, windings can allow high-frequency parasitic electrical currents to circulate entirely within the motor. A Wye-connected winding does not contain a closed loop in which parasitic currents can flow, preventing such losses.

From a controller standpoint, the two styles of windings can be treated exactly the same.