Lowest Price for 24v Brushless Dc Blower - mini turbo blower for 10kw fuel cell – Wonsmart

Lowest Price for 24v Brushless Dc Blower - mini turbo blower for 10kw fuel cell – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 48vdc

Bearing: NMB ball bearing

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Voltage:24VDC

Certification: ce, RoHS

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 3 Kgs

Housing material:PC

Unit size: D110*H107mm

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 30kPa

Drawing

Blower Performance

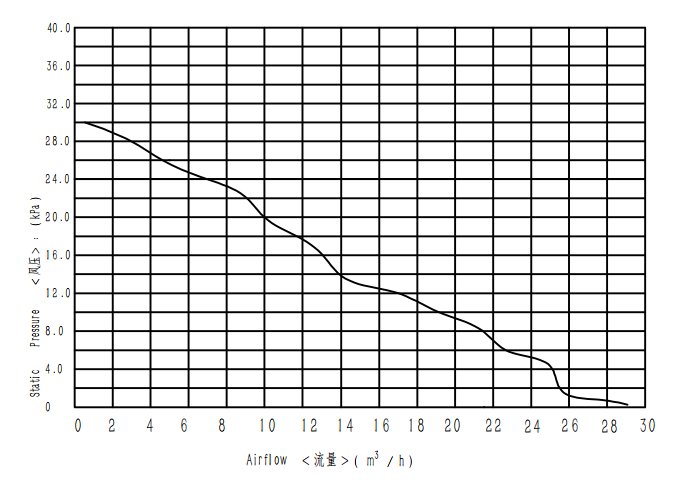

WS145110-48-150-X300-SR blower can reach maximum 29m3/h airflow at 0 kpa pressure and maximum 30kpa static pressure.It has maximum output air power when this blower run at 18kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 16kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS145110-48-150-X300-SR blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 30,000hours at 20degree C environmental temperature.

(2) This blower needs no maintence;

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto vacuum machine,fuel cell.

How to Use the Blower Correctly

This blower can run at CCW direction only.Reverse the impeller running direction can not change the air direction.

Filter onto the inlet to protect the blower from dust and water.

Keep the environmental temperature as low as possible to make the blower life time longer.

FAQ

Q: Can we connect this centrifugal air blower directly onto power source?

A: This blower fan is with BLDC motor inside and it needs a controller board to run.

Q: What kind of power source shall we use to drive this blower fan?

A: Generally, our customers use 24vdc switching power supply or Li-on battery.

Q: Do you also sell controller board for this blower fan?

A: Yes, we can supply adapted controller board for this blower fan.

When electrical and DC motor technology was first developed, much of the equipment was constantly tended by an operator trained in the management of motor systems. The very first motor management systems were almost completely manual, with an attendant starting and stopping the motors, cleaning the equipment, repairing any mechanical failures, and so forth.

The first DC motor-starters were also completely manual, as shown in this image. Normally it took the operator about ten seconds to slowly advance the rheostat across the contacts to gradually increase input power up to operating speed. There were two different classes of these rheostats, one used for starting only, and one for starting and speed regulation. The starting rheostat was less expensive, but had smaller resistance elements that would burn out if required to run a motor at a constant reduced speed.

This starter includes a no-voltage magnetic holding feature, which causes the rheostat to spring to the off position if power is lost, so that the motor does not later attempt to restart in the full-voltage position. It also has overcurrent protection that trips the lever to the off position if excessive current over a set amount is detected.

Product detail pictures:

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for Lowest Price for 24v Brushless Dc Blower - mini turbo blower for 10kw fuel cell – Wonsmart , The product will supply to all over the world, such as: Bulgaria, Ecuador, Cannes, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!