Special Design for Ventilator Centrifugal Blower Fan Dc 24v - Mini respirator centrifugal quiet inspirator ventilator cpap blower – Wonsmart

Special Design for Ventilator Centrifugal Blower Fan Dc 24v - Mini respirator centrifugal quiet inspirator ventilator cpap blower – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Voltage:24VDC

Certification: ce, RoHS, ETL

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 80 grams

Housing material:PC

Unit size: D70mm *H37mm

Motor type:Three Phase DC Brushless Motor

Outlet diameter: OD17mm ID12mm

Controller: external

Static pressure: 6.8kPa

Drawing

Blower Performance

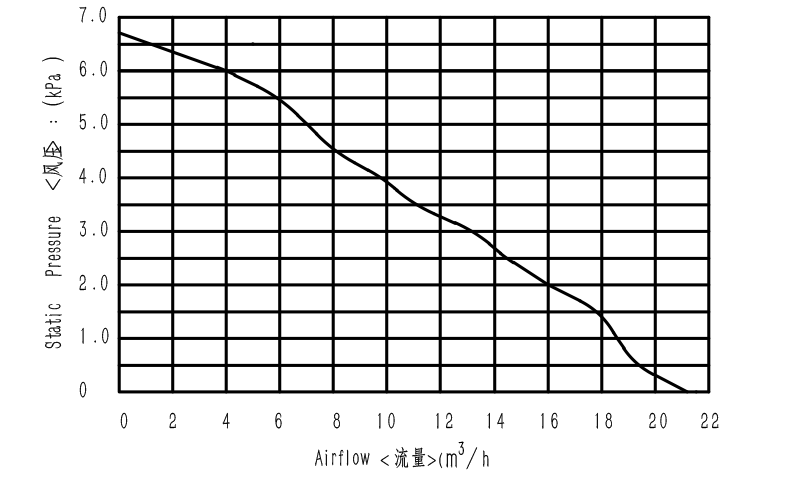

WS7040-24-V200 blower can reach maximum 22m3/h airflow at 0 kpa pressure and maximum 6.8kpa static pressure. It has maximum output air power when this blower run at 3kPa resistance if we set 100% PWM. It has maximum efficiency when this blower run at 5.5kPa resistance if we set 100% PWM. Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1)WS7040-24-V200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000 hours at 20 degree C environmental temperature.

(2)This blower needs no maintenance

(3)This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air cushion machine, CPAP machine, SMD soldering rework station.

How to Use the Blower Correctly

FAQ

Q:Customer: May I use this blower for Medical device?

A: Yes, this is one blower of our company which can be used on Cpap and ventilator.

Q: What’s is the maxmum air pressure?

A: As it shown in the drawing, the maxmum air pressure is 6.5 Kpa.

Compared with DC motor and asynchronous motor, the key technical characteristics of Brushless DC motor are:

1.The operating characteristics of DC motor are obtained by electronic control. It has better controllability and wide speed range.

2.Rotor position feedback information and electronic multiphase inverter driver are needed.

3.Essentially, AC motor can work at high speed without spark and abrasion of brush and commutator. It has high reliability, long working life and no need of maintenance.

4.Brushless DC motor has high power factor, no loss of rotor and heat, and high efficiency: compared with data, the efficiency of 7.5 kW asynchronous motor is 86.4%, and the efficiency of the same capacity brushless DC motor can reach 92.4%.

5.There must be electronic control parts, the total cost is higher than the DC motor.

There are mainly two kinds of motors used in AC system: induction motor and permanent magnet synchronous motor. Permanent magnet synchronous motor can be divided into sinusoidal back EMF permanent magnet synchronous motor (PMSM) and square wave back EMF brushless DC motor (BLDCM) according to different working principle. So that their driving current and control mode are different.

The back EMF of sinusoidal permanent magnet synchronous motor is sinusoidal. For the motor to produce smooth torque, the current flowing through the motor winding must be sinusoidal. Therefore, the continuous rotor position signal must be known, and the inverter can provide sinusoidal voltage or current to the motor. Therefore, PMSM needs to adopt high voltage or current. The resolution of the position encoder or resolver is also very complicated.

BLDCM does not need high-resolution position sensor, the feedback device is simple, and the control algorithm is relatively simple. In addition, the air gap magnetic field of BLDCM trapezoidal wave is more efficient than that of PMSM sinusoidal wave, and the power density of BLDCM is higher than that of PMSM. Therefore, the application and research of permanent magnet brushless DC motor has received more and more attention.

Product detail pictures:

Related Product Guide:

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we'll build a prosperous future together with your esteemed organization for Special Design for Ventilator Centrifugal Blower Fan Dc 24v - Mini respirator centrifugal quiet inspirator ventilator cpap blower – Wonsmart , The product will supply to all over the world, such as: Argentina, Mongolia, New Orleans, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.