Well-designed Low Noisy Dc Air Blower - Fast portable inflation blower for air bed – Wonsmart

Well-designed Low Noisy Dc Air Blower - Fast portable inflation blower for air bed – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Voltage:24VDC

Certification: ce, RoHS

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 420 grams

Housing material:PC

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 8kPa

Drawing

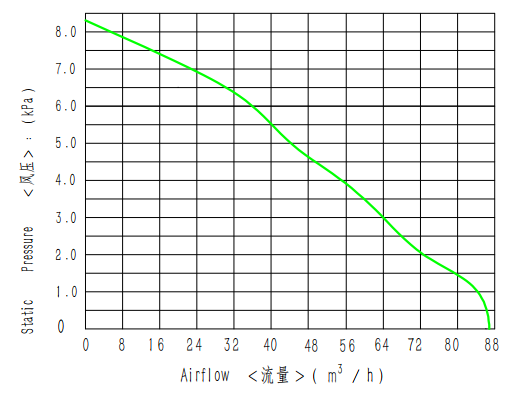

Blower Performance

WS9260-24-250-X200 blower can reach maximum 88m3/h airflow at 0 kpa pressure and maximum 13kpa static pressure.It has maximum output air power when this blower run at 4.5kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 4.5kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS9260-24-250-X200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20degree C environmental temperature.

(2) This blower needs no maintence;

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto combustion,air bed, and ventilation.

How to Use the Blower Correctly

FAQ

Q: May I use this blower for Medical device?

A: Yes, this is one blower of our company which can be used on Cpap and ventilator.

Q: What’s is the maxmum air pressure?

A: As it shown in the drawing, the maxmum air pressure is 6.5 Kpa.

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

In brushless DC motors, an electronic servo system replaces the mechanical commutator contacts. An electronic sensor detects the angle of the rotor and controls semiconductor switches such as transistors which switch current through the windings, either reversing the direction of the current or, in some motors turning it off, at the correct angle so the electromagnets create torque in one direction. The elimination of the sliding contact allows brushless motors to have less friction and longer life; their working life is only limited by the lifetime of their bearings.

Brushed DC motors develop a maximum torque when stationary, linearly decreasing as velocity increases. Some limitations of brushed motors can be overcome by brushless motors; they include higher efficiency and lower susceptibility to mechanical wear. These benefits come at the cost of potentially less rugged, more complex, and more expensive control electronics.

A typical brushless motor has permanent magnets that rotate around a fixed armature, eliminating problems associated with connecting current to the moving armature. An electronic controller replaces the commutator assembly of the brushed DC motor, which continually switches the phase to the windings to keep the motor turning. The controller performs similar timed power distribution by using a solid-state circuit rather than the commutator system.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of Well-designed Low Noisy Dc Air Blower - Fast portable inflation blower for air bed – Wonsmart , The product will supply to all over the world, such as: Nepal, Orlando, Estonia, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!