Wholesale Fan Blowers Centrifugal - Dc brushless mini electric centrifugal air blower fan – Wonsmart

Wholesale Fan Blowers Centrifugal - Dc brushless mini electric centrifugal air blower fan – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage:24vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries:Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS, ETL

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 490 grams

Housing material:PC

Unit size: D90*L114

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 13 kPa

Drawing

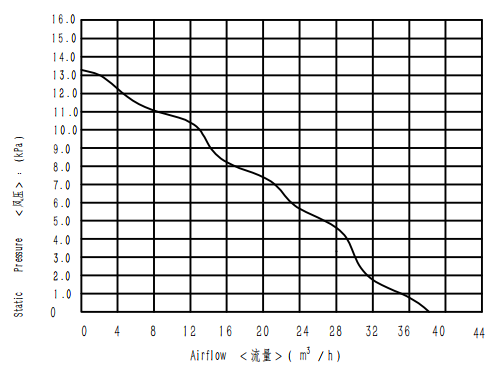

Blower Performance

WS9290B-24-220-X300 blower can reach maximum 38m3/h airflow at 0 kpa pressure and maximum 13kpa static pressure.It has maximum output air power when this blower run at 7kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 7kPa resistance if we set 100% PWM.Other load point performance refer to below P Q curve:

DC Brushless Blower Advantage

(1) WS9290B-24-220-X300blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000hours at 20degree C environmental temperature

(2) This blower needs no maintence

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air pollution detector,air bed,air cushion machine and ventilators.

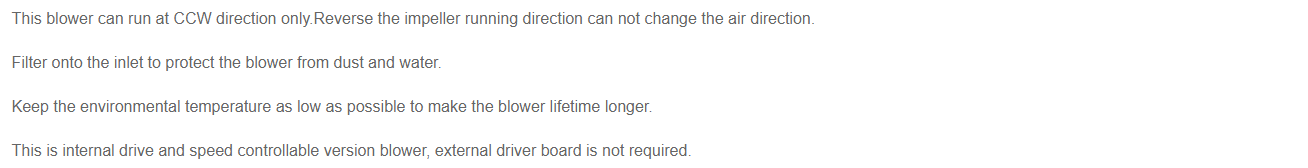

How to Use the Blower Correctly

FAQ

Q: Do you also sell controller board for this blower fan?

A: Yes, we can supply adapted controller board for this blower fan.

Q: How to change impeller speed if we use your controller board?

A: You can use 0~5v or PWM to change speed. Our standard controller board is also with a potentiometer to change speed conveniently.

The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary permanent magnets, and rotating electrical magnets. Brushes and springs carry the electric current from the commutator to the spinning wire windings of the rotor inside the motor. Brushless DC motors use a rotating permanent magnet in the rotor, and stationary electrical magnets on the motor housing. A motor controller converts DC to AC. This design is simpler than that of brushed motors because it eliminates the complication of transferring power from outside the motor to the spinning rotor. An example of a brushless, synchronous DC motor is a stepper motor which can divide a full rotation into a large number of steps.

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Wholesale Fan Blowers Centrifugal - Dc brushless mini electric centrifugal air blower fan – Wonsmart , The product will supply to all over the world, such as: Uruguay, Romania, Algeria, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We are able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and products. For anyone who is interested in our company and items, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please really feel no cost to speak to us for enterprise. nd we believe we are going to share the most effective trading practical experience with all our merchants.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!