Wholesale Fan Blowers Centrifugal - high speed centrifugal blower fan with brushless motor – Wonsmart

Wholesale Fan Blowers Centrifugal - high speed centrifugal blower fan with brushless motor – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 48vdc

Bearing: NMB ball bearing

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: aluminium

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 886 grams

Housing material:PC

Size: 130mm*120mm

Motor type:Three Phase DC Brushless Motor

Controller: external

Static pressure: 14kPa

Drawing

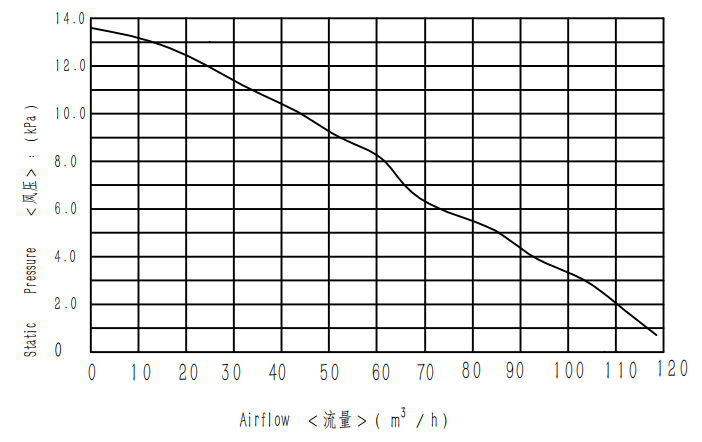

Blower Performance

WS130120S2-48-220-X300 blower can reach maximum 120m3/h airflow at 0 Kpa pressure and maximum 14kpa static pressure.It has maximum output air power when this blower run at 8.5 kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 8.5 kPa resistance if we set 100% PWM.Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS130120S2-48-220-X300 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 15,000hours at 20degree C environmental temperature.

(2) This blower needs no maintence

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily.

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto vacuum machine,dust collector,floor treatment machine.

How to Use the Blower Correctly

FAQ

Q: Are you factory or trading company?

A: We are factory with 4,000 square meters and we have been focus on high pressure BLDC blowers for more than 10 years

Q: Can we connect this centrifugal air blower directly onto power source?

A: This blower fan is with BLDC motor inside and it needs a controller board to run.

How Electric Motors Work

A brushed DC electric motor is an internally commutated electric motor designed to be run from a direct current power source. Brushed motors were the first commercially important application of electric power to driving mechanical energy, and DC distribution systems were used for more than 100 years to operate motors in commercial and industrial buildings. Brushed DC motors can be varied in speed by changing the operating voltage or the strength of the magnetic field. Depending on the connections of the field to the power supply, the speed and torque characteristics of a brushed motor can be altered to provide steady speed or speed inversely proportional to the mechanical load. Brushed motors continue to be used for electrical propulsion, cranes, paper machines and steel rolling mills. Since the brushes wear down and require replacement, brushless DC motors using power electronic devices have displaced brushed motors from many applications.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Wholesale Fan Blowers Centrifugal - high speed centrifugal blower fan with brushless motor – Wonsmart , The product will supply to all over the world, such as: Kazakhstan, Germany, Finland, We are your reliable partner in international markets with the best quality products. Our advantages are innovation, flexibility and reliability which have been built during the last twenty years. We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sales and after-sales service ensures strong competitiveness in an increasingly globalized market.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!