Wholesale Price Medical Air Blower - 12 Vdc mini centrifugal air blower fan – Wonsmart

Wholesale Price Medical Air Blower - 12 Vdc mini centrifugal air blower fan – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 12 vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries: Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS, ETL

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000hours (under 25 degree C)

Weight: 80 grams

Housing material:PC

Unit size: D70mm *H37mm

Motor type:Three Phase DC Brushless Motor

Outlet diameter: OD17mm ID12mm

Controller: external

Static pressure: 6.8kPa

Drawing

Blower Performance

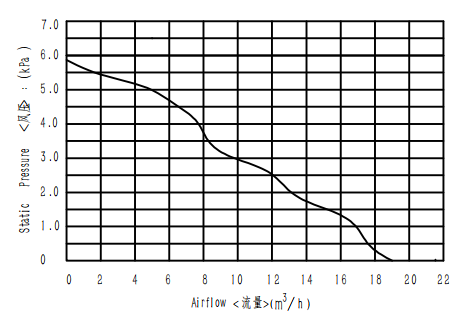

WS7040-12-X200 blower can reach maximum 18m3/h airflow at 0 kpa pressure and maximum 5.5kpa static pressure. It has maximum output air power when this blower run at 3kPa resistance if we set 100% PWM. It has maximum efficiency when this blower run at 5.5kPa resistance if we set 100% PWM. Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1) WS7040-12-X200 blower is with brushless motors and NMB ball bearings inside which indicates very long life time; MTTF of this blower can reach more than 20,000 hours at 20 degree C environmental temperature.

(2) This blower needs no maintence

(3) This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.it can be controlled by intelligent machine and equipment easily

(4) Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

Applications

This blower can be widely used onto air cushion machine, CPAP machine, SMD soldering rework station.

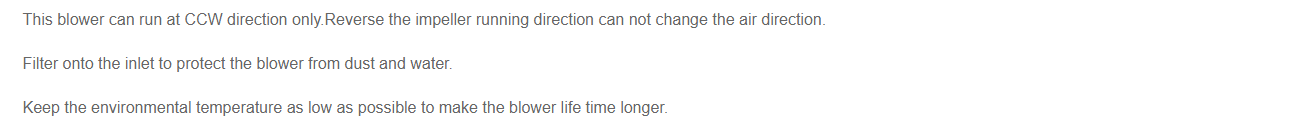

How to Use the Blower Correctly

FAQ

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

Q: What’s your after-sale service?

A: Our quality warranty period is one year. Any quality problem will be solved to customer satisfactions.

The centrifugal fan uses the centrifugal power supplied from the rotation of impellers to increase the kinetic energy of air/gases. When the impellers rotate, the gas particles near the impellers are thrown off from the impellers, then move into the fan casing. As a result, the kinetic energy of gas is measured as pressure because of the system resistance offered by the casing and duct. The gas is then guided to the exit via outlet ducts. After the gas is thrown-off, the gas pressure in the middle region of the impellers decreases. The gas from the impeller eye rushes in to normalize this. This cycle repeats and therefore the gas can be continuously transferred.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for Wholesale Price Medical Air Blower - 12 Vdc mini centrifugal air blower fan – Wonsmart , The product will supply to all over the world, such as: Rwanda, Egypt, Gabon, Ought to any of these products be of curiosity to you, remember to allow us to know. We are going to be satisfied to give you a quotation on receipt of one's in depth specs. We've our private experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.