Wholesale Suction Blower Fan - Low noise CPAP Blower – Wonsmart

Wholesale Suction Blower Fan - Low noise CPAP Blower – Wonsmart Detail:

Blower Features

Brand name: Wonsmart

High pressure with dc brushless motor

Blower type: Centrifugal fan

Voltage: 12 vdc

Bearing: NMB ball bearing

Type: Centrifugal Fan

Applicable Industries:Manufacturing Plant

Electric Current Type: DC

Blade Material: plastic

Mounting: Ceiling Fan

Place of Origin:Zhejiang, China

Certification: ce, RoHS,

Warranty: 1 Year

After-sales Service Provided: Online support

Life time(MTTF): >20,000 hours (under 25 degree C)

Weight: 63 grams

Housing material:PC

Controller: internal

Static pressure: 4.8kPa

Drawing

Blower Performance

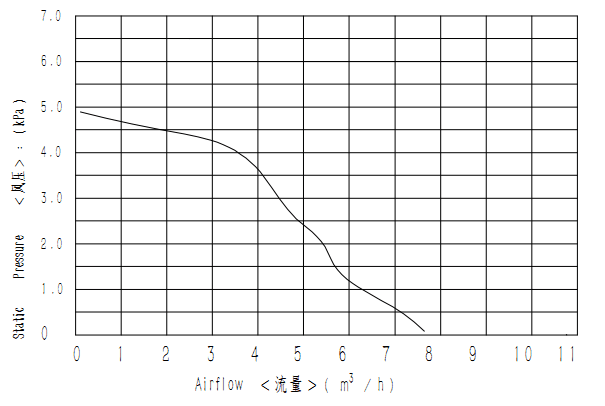

Low noise CPAP Blower can reach maximum 8m3/h airflow at 0 kpa pressure and maximum 4.8 kpa static pressure.It has maximum output air power when this blower run at 3kPa resistance if we set 100% PWM, It has maximum efficiency when this blower run at 3.5kPa resistance if we set 100% PWM. Other load point performance refer to below P-Q curve:

DC Brushless Blower Advantage

(1).Low noise CPAP blower is with brushless motors and NMB ball bearings inside which indicates very long life time

(2).MTTF of this blower can reach more than 20,000 hours at 20 degree C environmental temperature.

(3).This blower drived by a brushless motor controller have many different control functions such as speed regulation,speed pulse output,fast acceleration, brake etc.

(4).It can be controlled by intelligent machine and equipment easily.

Drived by brushless motor driver the blower will have over current, under/over voltage,stall protections.

How to Use the Blower Correctly

This blower can run at CCW direction only.Reverse the impeller running direction can not change the air direction.

Filter onto the inlet to protect the blower from dust and water.

Keep the environmental temperature as low as possible to make the blower lifetime longer.

This is internal drive and speed controllable version blower, external driver board is not required.

FAQ

Q: Can you design a new blower fan if we give you target performance?

A: Yes, we offer ODM service for both blower fan and controller board.

Q: What can do if the working condition is dirty?

A: A filter is strongly recommended to assemble onto the the inlet of the blower fan

Q: How to decrease the noise of the blower?

A: Many of our customers use foam, silicone to fill between blower fan and machine to insulate the blower noise.

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are a sub-class of dynamic axisymmetric work-absorbing turbomachinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits.

Common uses include water, sewage, agriculture, petroleum and petrochemical pumping. Centrifugal pumps are often chosen for their high flow rate capabilities, abrasive solution compatibility, mixing potential, as well as their relatively simple engineering. A centrifugal fan is commonly used to implement an air handling unit or vacuum cleaner. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy.

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, constantly regards product good quality as organization life, constantly improve production technology, strengthen merchandise high quality and continuously strengthen enterprise total good quality administration, in strict accordance with all the national standard ISO 9001:2000 for Wholesale Suction Blower Fan - Low noise CPAP Blower – Wonsmart , The product will supply to all over the world, such as: Belarus, Portland, Bulgaria, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!